Understanding Oxy Acetylene Welding Kits

What is an Oxy Acetylene Welding Kit?

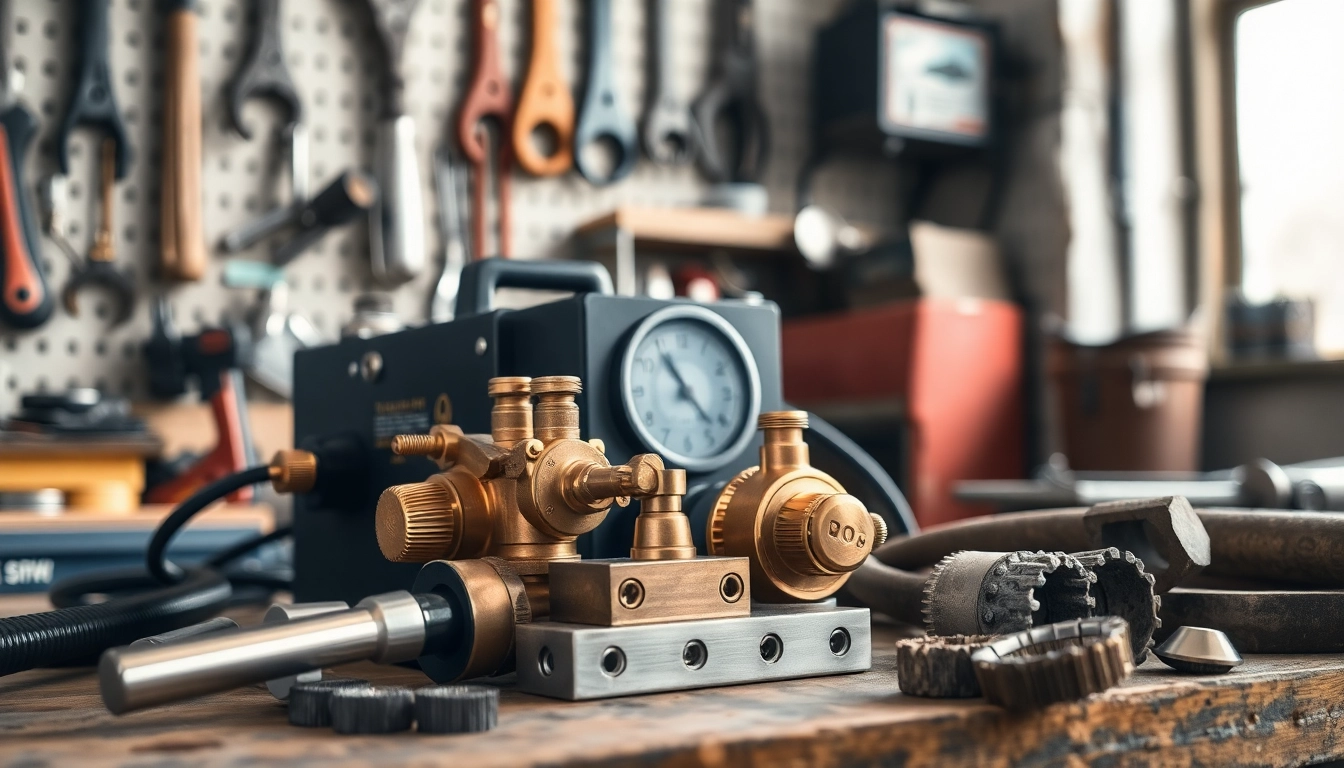

An oxy acetylene welding kit is a versatile ensemble of tools designed to facilitate the welding and cutting of various materials, primarily metals. This method combines oxygen and acetylene gases to generate a high-temperature flame, commonly ranging from 3,200 to 3,500 degrees Celsius. This extreme heat allows for the melting of metals, enabling either welding or cutting processes, depending on the techniques and tools employed.

These kits are essential in many industries, including automotive repair, metal fabrication, HVAC installation, and plumbing. For those interested in purchasing equipment, you can explore options like the oxy acetylene welding kit that features a variety of essential components tailored for both beginners and experienced welders.

Essential Components of the Kit

An oxy acetylene welding kit typically comprises several key components:

- Oxygen and Acetylene Cylinders: These are the gas storage tanks that provide the fuels necessary for combustion.

- Regulators: These devices control the pressure of the gases flowing from the cylinders to the torch.

- Torch: The tool that mixes the gases and ignites them to produce the welding flame.

- Hoses: Flexible tubing that connects the cylinders to the regulators and the torch, allowing for safe transport of the gases.

- Welding Goggles or Helmet: Essential for eye protection from bright flames and UV radiation.

- Welding Tips: Different tips will allow for various flame types, classified as neutral, oxidizing, or carburizing flames depending on the project needs.

How Oxy Acetylene Works for Welding

The process of oxy acetylene welding involves the mixing of oxygen and acetylene gases in specific proportions. When ignited, the combustion produces a high-temperature flame which can achieve sufficient heat to melt metals. The primary technique used in welding is the introduction of a filler material, which is melted in conjunction with the base metals being joined, creating a strong bond as it cools.

Understanding flame types is crucial for successful welding:

- Neutral Flame: Ideal for most welding applications, it has equal amounts of oxygen and acetylene.

- Oxidizing Flame: Contains excess oxygen; beneficial for welding certain metals but can be detrimental to others.

- Carburizing Flame: Excess acetylene is present, producing a reducing environment that can prevent oxidation.

Benefits of Using an Oxy Acetylene Welding Kit

Versatility in Welding Applications

Oxy acetylene welding kits are renowned for their versatility. They can be used for a variety of applications, including welding, cutting, brazing, and even heating. This flexibility makes them suitable for both light-duty tasks and heavy fabrication projects.

Whether you are working with thin sheet metal or thicker steel, the capability to adjust the flame size and heat makes this tool indispensable in many settings. The ease of switching between welding and cutting modes further enhances its utility, allowing users to achieve precise results in various situations.

Efficiency and Cost-Effectiveness

In terms of efficiency, oxy acetylene welding kits provide a fast solution for joining metals. The heating speed allows for minimal distortion in the welded materials, leading to high-quality, robust joints with less time spent on setup and adjustments. While the initial investment might seem steep, the longevity and productivity gains from using an oxy acetylene kit often outweigh the costs.

Additionally, with proper care and maintenance, these kits can last for years, making them a worthwhile investment for both amateurs and professionals in the welding field.

Portability and Ease of Use

Most oxy acetylene welding kits are designed with portability in mind. The gas cylinders, though heavy, can be transported relatively easily when using appropriate carts or stands. Many kits come with case options that make them manageable for fieldwork or transportation between job sites.

Moreover, the setup process is straightforward. Once familiarized with the components and processes, users can operate the system with a degree of comfort that promotes efficiency in their tasks. For beginners, numerous available resources and tutorials can help them quickly gain confidence in using this equipment.

Choosing the Right Oxy Acetylene Welding Kit for Your Needs

Factors to Consider When Selecting a Kit

Selecting the right oxy acetylene welding kit can be overwhelming, given the variety of options available on the market. Here are the key factors to consider when making your decision:

- Intended Use: Identify whether you will primarily be welding thin metals, doing heavy fabrication, or requiring portable solutions for repairs.

- Tank Size: Consider the cylinder sizes based on portability and frequency of use; larger tanks will last longer but can be cumbersome.

- Brand Reputation: Opt for well-known brands that offer quality products and customer service. Research reviews and testimonials.

- Included Accessories: Ensure the kit comes with essential accessories suited for your specific needs to avoid additional costs later.

Beginner vs. Professional Kits

When choosing between beginner and professional oxy acetylene welding kits, it’s essential to assess the skill level and intended projects of the user. Beginner kits often come with basic components, are user-friendly, and may include instructional material to help new welders learn the ropes. Conversely, professional kits usually incorporate advanced features and higher-capacity tanks designed for extensive or heavy-duty welding applications.

For novices, selecting a kit that allows for growth in skill and application can be beneficial, while seasoned professionals may prioritize efficiency, durability, and specific capabilities of the equipment they select.

Brand Comparisons and Customer Reviews

It’s always advisable to compare brands and read customer reviews. Many reputable manufacturers offer quality oxy acetylene welding kits, each with its strengths and weaknesses. Consider elements such as user-friendliness, customer service, warranty, and quality of components, which can significantly influence the overall satisfaction with your purchase.

Online resources, such as forums and manufacturer websites, can provide insights into practical experiences with different kits, allowing potential buyers to make informed decisions based on real user feedback and expert opinions.

Safety Tips for Using Oxy Acetylene Welding Kits

Personal Protective Equipment (PPE) Requirements

Safety should always be the top priority when operating an oxy acetylene welding kit. Make sure to wear appropriate PPE, which includes:

- Welding Goggles or Helmet: Protects against harmful UV rays and intense brightness.

- Gloves: Durable gloves to protect hands from heat and accidental injuries.

- Long Sleeve Clothing: Wear natural fibers like cotton or wool, which are less likely to catch fire compared to synthetic materials.

- Respiratory Protection: In poorly ventilated spaces, consider using respirators to protect against toxic fumes.

Best Practices for Safe Operation

Implement these guidelines for safe operation of your oxy acetylene welding kit:

- Read Manufacturer Instructions: Always be familiar with your equipment’s manual and operation protocols.

- Check Equipment Regularly: Inspect hoses, regulators, and tanks for damage or wear before each use.

- Work in a Ventilated Area: Ensure your workspace is well-ventilated to avoid toxic fumes accumulation.

- Avoid Flammable Materials: Keep the working area free from flammable debris or liquids that could ignite unexpectedly.

- Control Flammable Gas Release: Always shut off the gas supply when the welding job is completed or when leaving the workstation.

Handling and Storing Gas Cylinders Safely

Gas cylinders should be treated with respect and care to prevent accidents. Here are some guidelines for safe handling and storage:

- Secure Cylinders: Always store gas cylinders securely, upright and in a designated area away from heat sources.

- Use Cylinder Carts: If moving cylinders, use appropriate carts to transport them safely.

- Protect Cylinder Valves: Ensure cylinder valves are closed tightly and protected from damage.

- Separate Storage: Store oxygen and acetylene cylinders separately to prevent accidental reactions.

Common Issues and Troubleshooting with Oxy Acetylene Welding Kits

Identifying Flame and Gas Flow Problems

Flame and gas flow issues are not uncommon in oxy acetylene welding. Recognizing and addressing specific problems can save time and enhance safety:

- Flame Too Weak: This may indicate insufficient gas flow; check your regulators and hoses for blockages or leaks.

- Flame Too Hissing or Rough: This can suggest improper mixer settings or gas mixtures; adjustments may be required.

- Flame Color Changes: A color change from blue to yellow could indicate a problem with the combustion process, necessitating investigation.

Understanding Welding Defects and Solutions

Welding defects such as porosity, slag inclusions, and burn-through can undermine the integrity of finished welds. These issues often arise from operator technique or equipment settings:

- Porosity: This occurs due to trapped gasses in the weld. Ensure the base metal is clean and free from moisture or contaminants.

- Slag Inclusions: Typically found in metal components, these can happen if slag isn’t cleaned between passes. Ensure thorough cleaning between welds.

- Brittle Welds: This can result from overheating or poor filler material. Regularly check the operating temperature and material compatibility.

When to Seek Professional Help

If issues persist despite following troubleshooting steps, it may be prudent to seek professional help. Consult with experienced welders or technicians when:

- Unresolved equipment malfunctions or gas leaks are suspected.

- There are repeated failures in achieving desired welding quality.

- Safety concerns arise that exceed your expertise or comfort level.

Ultimately, having a reliable oxy acetylene welding kit is indispensable for many welding tasks. Armed with a better understanding of its components, benefits, safety considerations, and troubleshooting methods, both beginners and seasoned professionals can navigate the world of welding with greater ease and confidence.